Hydrohytos Industries Pvt. Ltd.

We manufacturing Customized Hydraulic and Precision Engineering Components with Excellence, Innovation, and Reliability Across Diverse Industrial Applications

We specialize in the manufacturing of customized precision components designed for a wide range of hydraulic and general engineering applications. Our goal is to deliver solutions that meet the highest standards of performance, accuracy, and reliability.

We combine advanced CNC and VMC machining technologies with experienced craftsmanship and in-house design expertise to produce components that meet exact customer specifications. Every part is carefully manufactured under strict quality control procedures to ensure precision, durability, and consistent results across every batch.

Our product range includes shafts, pins, flanges, housings, spacers, fasteners, sleeves, and subassemblies, all engineered to perform under demanding industrial conditions. Each component undergoes thorough inspection and testing to guarantee dimensional accuracy and material integrity.

At Hydrohytos, we are driven by engineering excellence and customer satisfaction. From prototype to production, we deliver end-to-end manufacturing solutions that help our clients achieve superior performance, efficiency, and long-term value.

Years of Experience

No. of Product

Employee Strength

Infrastructure (Sq. Ft.)

Precision Components

Our advanced CNC and VMC machining facilities enable the production of high precision components for demanding industries.

Our Commitment

“Hydrohytos Industries Pvt Ltd is committed to continuous improvement in our manufacturing processes to ensure the highest quality hydraulic cylinders for our customers and also environmentally sustainable.”

ISO-Certified Excellence

We deliver components that meet international quality standards, ensuring trust and reliability in every part.

Precision & Accuracy

Each component is manufactured with tight tolerances, guaranteeing consistent performance across all applications.

Modern Infrastructure

Equipped with CNC, VMC, honing, and advanced setups, we produce complex parts with high efficiency and durability.

Customer-Centric Approach

Every solution is tailored to customer requirements, ensuring value, satisfaction, and long-term partnerships.

Sample & Prototyping

We provide validation samples and prototypes, enabling customers to test, approve, and optimize product performance.

Strict Quality Checks

Each part undergoes rigorous testing with advanced inspection tools, ensuring flaw-free and reliable final output.

Technical Collaboration

Our experts assist in design and process optimization, helping customers achieve better efficiency and cost savings.

Timely Delivery

We ensure short lead times and reliable supply schedules, helping customers maintain smooth and uninterrupted operations.

Facilities

Hydrohytos operates a modern machining facility equipped to produce precision components with tight tolerances and consistent quality

CNC Machining

Our CNC machining facility delivers high-precision components with tight tolerances and consistent accuracy, ensuring efficiency and reliability across applications.

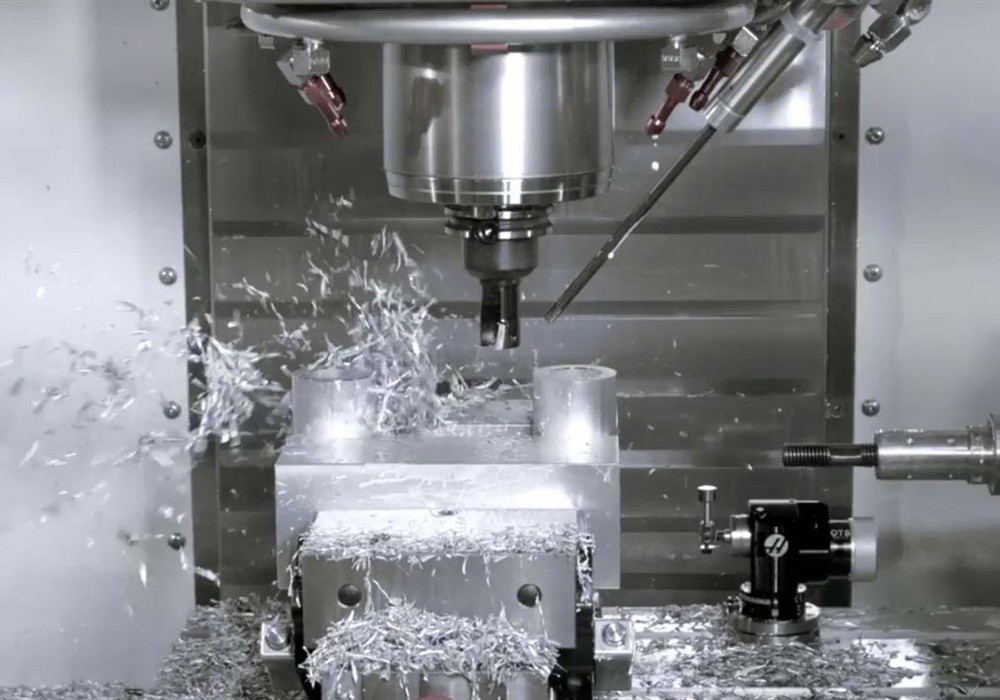

VMC Machining

Ensures accurate machining of complex parts with superior surface finishing, dimensional precision, and flexibility for varied engineering needs.

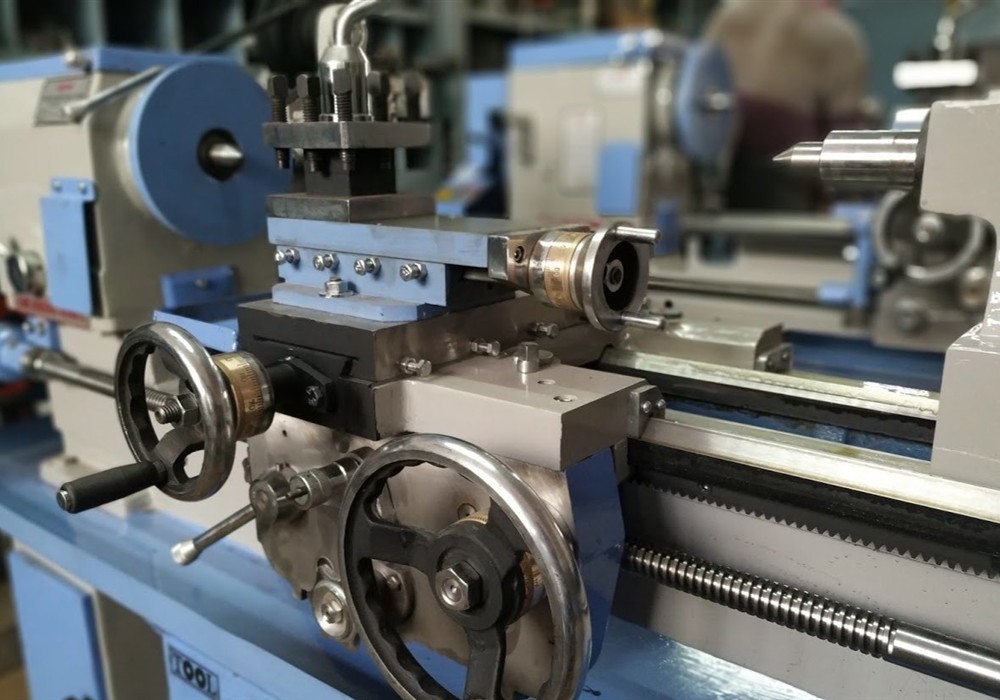

Conventional Lathe Machines

Reliable setup for turning, threading, and shaping cylindrical parts, ideal for shafts, pins, and spacers requiring accuracy and smooth finishing.

Milling Machines

Provides accurate cutting, slotting, and contouring for diverse components, ensuring precision in machining flat, angled, or irregular surfaces.

Radial Drilling Machines

Capable of drilling, tapping, and reaming large or heavy workpieces with precision, supporting flexible and accurate hole-making operations.

Circular & Band Saw

Enables efficient cutting of raw materials into accurate sizes, ensuring smooth finishes and reducing wastage for further machining processes.

Honing (ID Finishing) Machine

Achieves precise bore sizing and fine surface finishing, improving wear resistance, performance, and durability of critical components.

Ultrasonic Cleaning Machine

Uses ultrasonic waves for deep cleaning of components, removing oil, dust, and impurities while ensuring spotless and contamination-free parts.

Vibro Deburring Unit

Provides smooth finishing by removing burrs and sharp edges from machined parts, enhancing safety, accuracy, and overall component quality.

Tool Room Setup

Equipped with essential tools and equipment to support machining, repair, and maintenance, ensuring continuous production and efficiency.

ARC & MIG Welding Machines

Supports high-quality welding of metal parts, ensuring strong, durable joints suitable for structural and industrial applications.

Automatic Tapping Machine

Enables fast and accurate threading operations, improving productivity and precision in producing tapped holes for various components.

Industries We Serve

Hydrohytos Industries Pvt Ltd serves a diverse range of industries and segments, providing precision-engineered

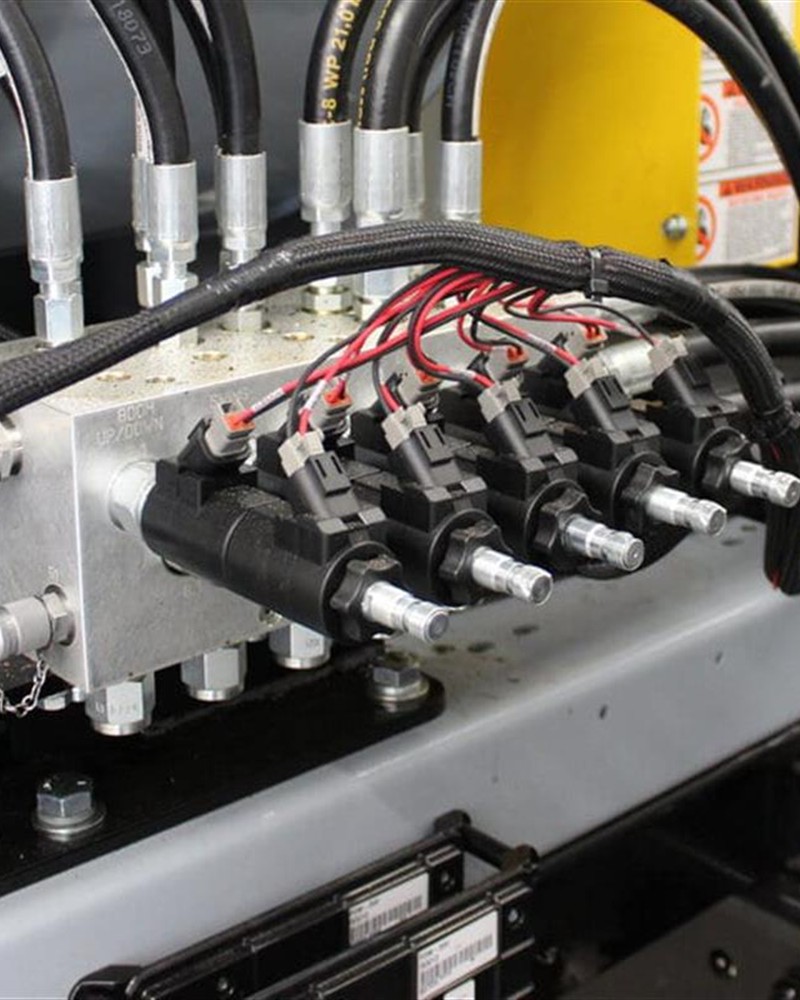

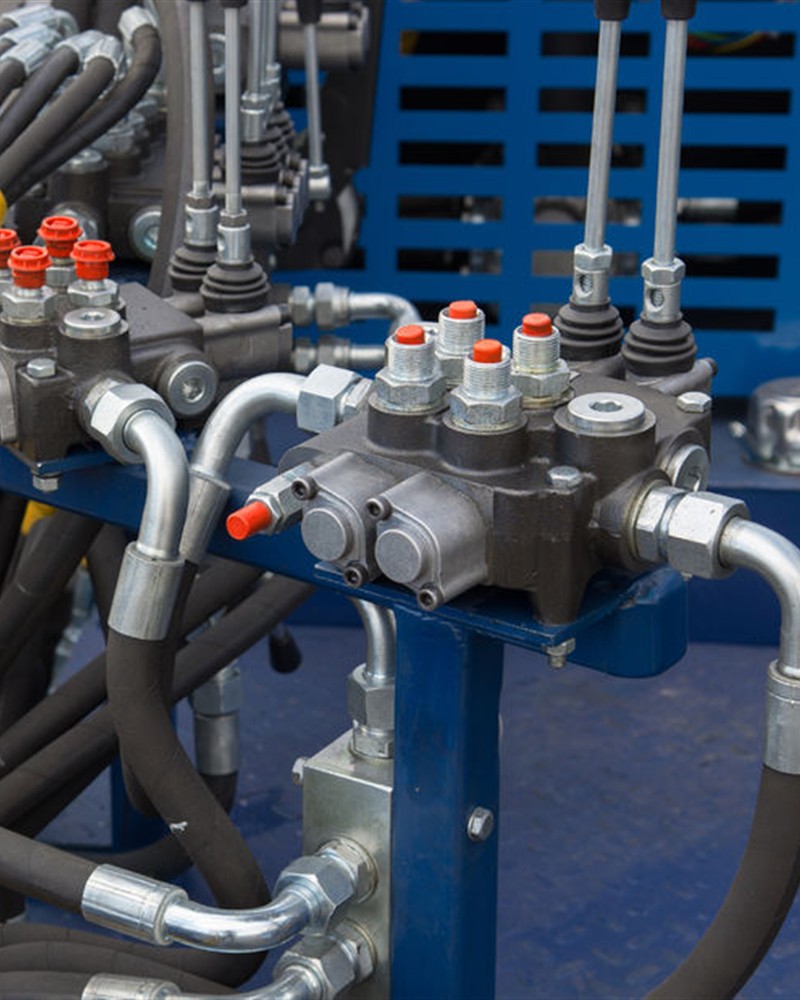

Hydraulic & Pneumatic

Precision parts for high-pressure fluid power systems ensuring seamless motion and control.

Manifolds & Valves

Custom-engineered blocks and valves for optimized fluid distribution and regulation.

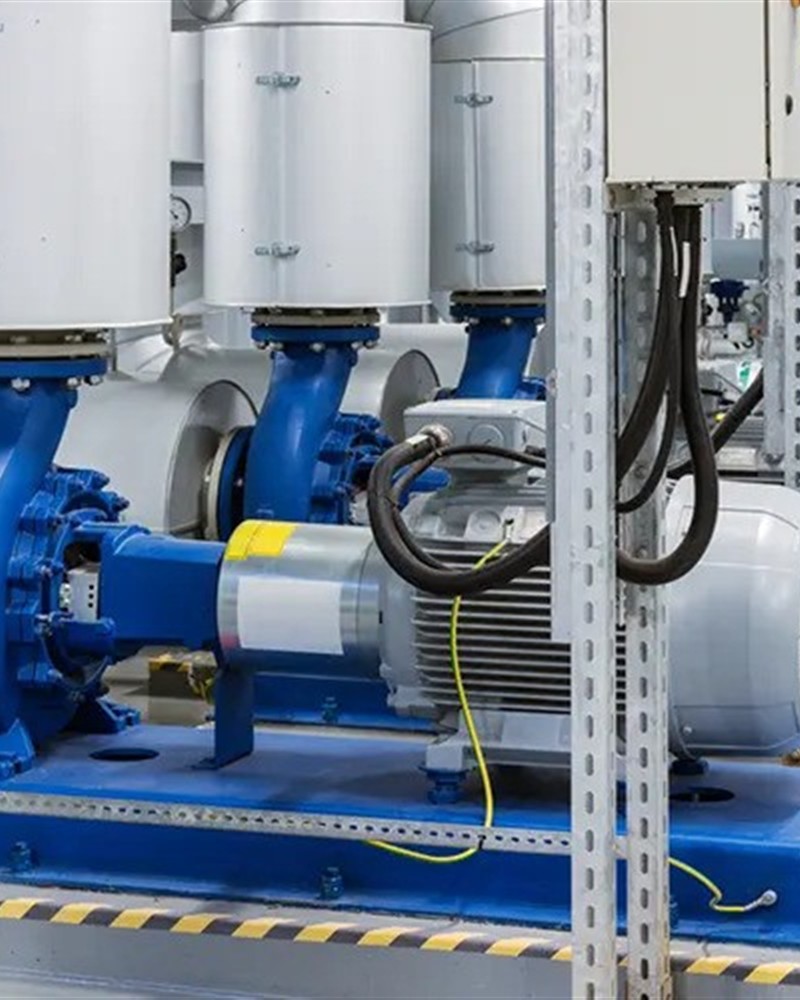

Pumps

Critical components for efficient fluid movement in various mechanical and industrial systems.

Aerospace

High-tolerance parts for aircraft systems, built to meet stringent safety and performance standards.

Automotive

Components for engines, drivetrains, and systems, supporting performance, durability, and efficiency.

Capital Goods

Robust parts for machinery and equipment used in industrial production processes.

Construction Equipment

Heavy-duty components built to withstand tough operational environments and workloads.

Energy

Precision-engineered parts for conventional and renewable energy generation systems.

Oil & Gas

Corrosion-resistant components for exploration, drilling, and refining operations.

Chemical & Pharma

Safe, clean, and reliable parts for fluid transfer and process control in regulated industries.

Agriculture

Durable parts for farming machinery and irrigation systems that drive agricultural productivity.

General Engineering

Versatile components tailored for a variety of industrial and mechanical engineering needs.

Material Handling

Parts that enable efficient movement, lifting, and transport in logistics and warehousing.

Surgical Implants

Precision medical components manufactured under stringent hygiene and quality standards.

Food Processing

Hygienic, corrosion-resistant components suitable for food-grade applications and machinery.

Electricals

High-precision parts for electrical enclosures, switchgear, and energy distribution systems.

Mining

Heavy-duty components that perform reliably in extreme underground and surface conditions.

Earth Moving

Tough, wear-resistant parts for loaders, excavators, and earth-moving machinery.

Machine Tools

Precision parts and accessories essential for metal cutting, shaping, and fabrication equipment.

Steel Plants

Heat-resistant components designed for demanding environments in steel manufacturing.