About Company

Hydrohytos Industries Pvt. Ltd.

We manufacturing Customized Hydraulic and Precision Engineering Components with Excellence, Innovation, and Reliability Across Diverse Industrial Applications

At Hydrohytos Industries Pvt. Ltd., we specialize in the manufacturing of customized precision components that cater to a wide spectrum of engineering applications. Our state-of-the-art facilities include CNC Turning Centers, VMC machines, honing, milling, drilling, and quality control units, enabling us to deliver components with unmatched accuracy and consistency.

Our product range covers shafts, pins, flanges, housings, spacers, fasteners, and subassemblies, all designed and produced to meet specific customer requirements. With ISO-certified processes, in-house design expertise, and strict inspection systems, we ensure dimensional accuracy, material integrity, and long-term performance in every part.

Driven by innovation, reliability, and customer focus, Hydrohytos Industries has built a reputation as a trusted partner for industries requiring precision and efficiency. Whether it is prototypes, batch production, or large-scale supply, we are committed to providing solutions that empower our customers’ growth and success.

With a strong commitment to continuous improvement and advanced technology, we constantly upgrade our facilities and practices to meet global standards. Our goal is not only to manufacture components but also to deliver value-added solutions that support customers in achieving higher productivity, reduced downtime, and sustainable growth.

Vision

Hydrohytos aims to be a globally trusted name in precision-engineered components through Technical excellence and reliability

Mission

To deliver Customized Machined Solutions with high accuracy and quality that support industrial growth.

Goal

Hydrohytos strives to expand in OEM and export markets, offering end-to-end Precise Machine component manufacturing solutions.

Years of Experience

No. of Product

Employee Strength

Infrastructure (Sq. Ft.)

Facilities

Hydrohytos operates a modern machining facility equipped to produce precision components with tight tolerances and consistent quality

CNC Machining

Our CNC machining facility delivers high-precision components with tight tolerances and consistent accuracy, ensuring efficiency and reliability across applications.

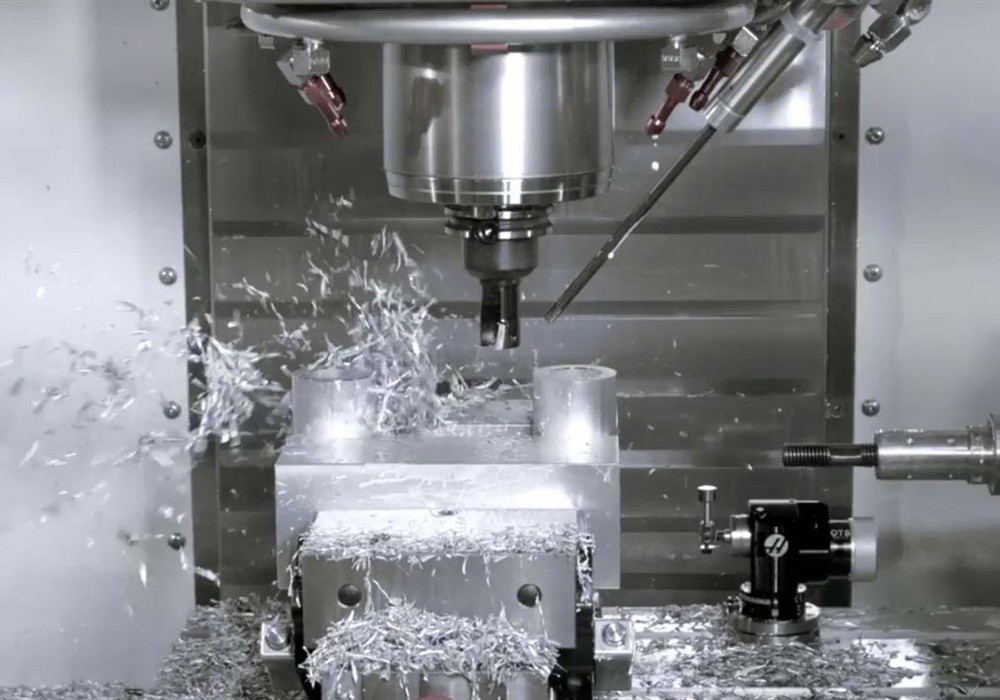

VMC Machining

Ensures accurate machining of complex parts with superior surface finishing, dimensional precision, and flexibility for varied engineering needs.

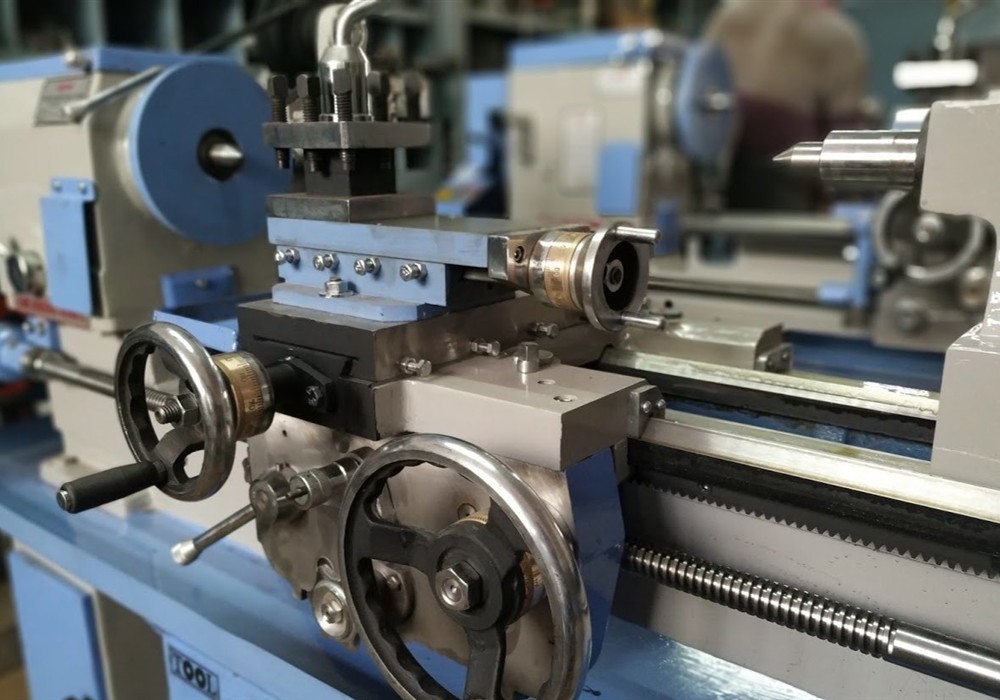

Conventional Lathe Machines

Reliable setup for turning, threading, and shaping cylindrical parts, ideal for shafts, pins, and spacers requiring accuracy and smooth finishing.

Milling Machines

Provides accurate cutting, slotting, and contouring for diverse components, ensuring precision in machining flat, angled, or irregular surfaces.

Radial Drilling Machines

Capable of drilling, tapping, and reaming large or heavy workpieces with precision, supporting flexible and accurate hole-making operations.

Circular & Band Saw

Enables efficient cutting of raw materials into accurate sizes, ensuring smooth finishes and reducing wastage for further machining processes.

Honing (ID Finishing) Machine

Achieves precise bore sizing and fine surface finishing, improving wear resistance, performance, and durability of critical components.

Ultrasonic Cleaning Machine

Uses ultrasonic waves for deep cleaning of components, removing oil, dust, and impurities while ensuring spotless and contamination-free parts.

Vibro Deburring Unit

Provides smooth finishing by removing burrs and sharp edges from machined parts, enhancing safety, accuracy, and overall component quality.

Tool Room Setup

Equipped with essential tools and equipment to support machining, repair, and maintenance, ensuring continuous production and efficiency.

ARC & MIG Welding Machines

Supports high-quality welding of metal parts, ensuring strong, durable joints suitable for structural and industrial applications.

Automatic Tapping Machine

Enables fast and accurate threading operations, improving productivity and precision in producing tapped holes for various components.

Why Work With Us

Choosing the right partner for precision components is critical. At Hydrohytos Industries, we combine advanced technology, skilled expertise, and ISO-certified systems to deliver consistent quality, reliability, and customer-focused solutions. Here’s why industries trust us.

End-to-End Capability

From raw material cutting to machining, finishing, and quality testing, we handle the complete process in-house. This ensures better control, faster response times, and reliable delivery of precision-engineered components tailored to customer needs.

Skilled Expertise

Our team of trained engineers and machinists brings deep knowledge of CNC, VMC, and conventional machining. Their expertise ensures every component meets exact technical specifications, delivering dependable performance for industries with demanding standards.

Consistent Reliability

With ISO-certified systems, modern facilities, and strict inspection processes, we guarantee stable output batch after batch. Customers rely on us for consistent accuracy, durability, and performance across every part, ensuring efficiency and trust in operations.

Trusted Partnerships

We believe in long-term customer relationships built on transparency, commitment, and service. By providing custom solutions, technical support, and dependable supply, we position ourselves as a trusted partner in our customers’ growth and success.